For research, our center is equipped with a modern laboratory and chemical-analytical.

Development and implementation of highly efficient and environmentally safe hydrometallurgical technologies for mineral processing, taking into account the forecasts of engineering and technology development, scientific and technical marketing and the latest achievements in science and technology.

In 2007, Petropavlovsk management decided to create a research center. In 2008, the research center “Hydrometallurgy” was established. Professor Ya. M. Schneerson, Doctor of Technical Sciences, stood at the origins of its creation. Within a year, the laboratory equipment of the entire center was installed, tested, and put into operation.

The complexity of the tasks set for the center predetermined both the quality of laboratory equipment and the specificity of staff selection: scientists with a reputation in hydrometallurgy (Ya. M. Schneerson, L. V. Chugaev), professionals with considerable experience in the hydrometallurgical industry (M. V. Klement’ev, A. Yu. Lapin and others), and young and active specialists with high growth potential.

This approach made it possible not to be limited to one vector of development of the center related to the recovery of refractory gold, but to constantly expand the range of research, interests and work performed.

- Autoclave section

- Laboratory of analytical control

- Fire assaying site

- Gold cyanidation site

- Wastewater and gas emission neutralization site

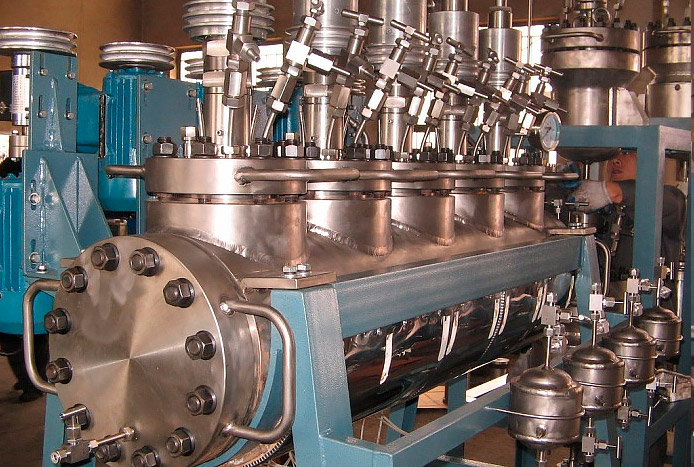

Simultaneously with putting the laboratory equipment into operation, the creation of an autoclave pilot plant (APP) was started to test the technological processes in a continuous enlarged mode.

In 2009, the designers of the PHM Engineering company made a design for the pilot plant on the site of the Pilot Shop for ore enrichment of Pokrovsky Rudnik OJSC (Blagoveshchensk).

In 2010, the construction and completion of the APU of a continuous pilot autoclave with a volume of 50 litres is carried out.

In April 2011 the pilot autoclave was put into operation. The unit is fully automated and controlled remotely.

The first major work of the center was the Pokrovsk Autoclave-Hydrometallurgy Complex of Petropavlovsk Company (PAGC) project. This large-scale project has lasted from 2009 to the present and includes a wide range of scientific and technical works and services, in particular:

- Development of the technology for gold recovery from ores of Malomyr and Pioneer deposits

- Support for the design of the industrial facility

- Participation in the selection of major equipment, support for its manufacture and delivery to the industrial site of PAGK

- Drawing up technological instructions for the autoclave-hydrometallurgical complex and training the personnel

- Participation in commissioning works

At the same time, the center has been actively and efficiently cooperating with Russian and foreign customers. Research works on testing technological properties of ores and concentrates of noble and non-ferrous metals, development of extraction technologies, technological and analytical support of existing and projected productions are carried out.