NIETZ TECHNOLOGIESAUTOCLAVE PILOT PLANT

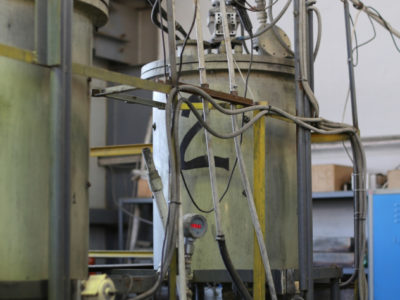

Autoclave Pilot Plant (APP) was commissioned in April 2011 and is located at the Pilot Shop for ore enrichment of JSC “Pokrovsky Mine” (Blagoveshensk). The autoclave is designed for pilot tests of polymetallic raw materials (ores and concentrates) autoclave treatment in a continuous mode at temperatures up to 250 °С and total pressure up to 4.5 MPa.

CONDITIONS OF AUTOCLAVE PROCESS AT APP CAN DIFFER:

- The type of initial solution or environment that occurs during the process.

- The presence in the gas phase of oxidizing agents (oxygen, air) or the absence of feed gases.

- Feeding reagents directly into the autoclave.

APP ALLOWS THE FOLLOWING AUTOCLAVE PROCESSES TO BE CARRIED OUT IN CONTINUOUS MODE:

- Oxidation of gold-containing sulfide raw materials for the destruction of sulfides (pyrite, arsenopyrite, etc.) that prevent recovery of the precious metal.

- Oxidation of polymetallic sulphide raw materials for the extraction (transfer to a solution) of valuable components (copper, zinc, etc.).

- Processing of oxidized ores with the transfer of valuable components to the solution (nickel, etc.).

- Hydrothermal enrichment of copper sulfide concentrates for copper (by a factor of 2 or more) by dissolving other components (zinc, iron and sulfur).

APP IS SUPPLIED WITH UP-TO-DATE EQUIPMENT THAT ALLOWS SEVERAL HYDROMETALLURGICAL OPERATIONS TO BE CARRIED OUT ON AN ENLARGED SCALE:

- Preparation of initial raw material before autoclave feeding (grinding, acid treatment, washing, temperature treatment (firing), etc.).

- Conditioning (temperature treatment) of autoclave slurries to improve the quality of intermediate products.

- Dewatering of autoclave slurries (thickening and filtration).

- Neutralization of acidic autoclave solutions.

- Neutralization and cyanidation of autoclave residues.

For all conducted operations, the necessary technological parameters are determined for further use in the selection of equipment.

APP flowsheet

The flowsheet of the autoclave pilot plant is shown in the following figure:

PYROMETALLURGICAL PILOT PLANT

Nabertherm RSRC 120-1000/11 Rotary tubular furnace

Nietz Technologies can carry out continuous firing tests on various materials at the pilot plant located at the Pilot Shop for Ore enrichment at the JSC Pokrovsky Mine (Blagoveshchensk).

The roasting is carried out in a rotary tube furnace.

- Maximum temperature 1100°C

- Variable speed of rotation approx. 2-45 rpm

- Digital angle indicator for furnace

- Three-zone regulation for optimal temperature consistency

- Temperature indicator in the furnace