The Center is equipped with modern laboratory and chemical-analytical equipment, which allows us to perform all types of complex studies and obtain reliable results.

In addition to the above equipment, Nietz Technologies is equipped with apparatuses for crushing and grinding ores and concentrates, flotation enrichment tests, as well as various types of reactors for atmospheric processes.

Technical equipmentAUTOCLAVE PRESSURE OXIDATION

- Automatic temperature, pressure, and stirrer speed control

- A continuous feed of gaseous and liquid reagents (Chrom Tech P1100 dosing pump)

- Slurry sampling under pressure

- Visual assessment of mixing conditions

For process control we use:

- Gas pressure and flow control system

- O2 and CO2 gas analyzers

- System for automatic on-line control and monitoring of the autoclave process

Technical equipmentSAMPLE PREP AND PARTICLE SIZE ANALYSIS

Analysette 3 Pro Fritsch vibroshaker screen

Designed for dry, wet and precision micro-screening with amplitude control, with a large set of accessories and AUTOSIEB software.

Analysette 22 Compact Fritsch laser particle analyzer

The multi-purpose device allows you to determine with high accuracy the size of particles in dry substances, emulsions, suspensions and various laboratory samples.

Technical equipmentATMOSPHERIC LEACHING

Cascade of reactors

The unit is designed for hydrometallurgical operations in continuous mode.

Technical specifications:

- Number of reactors: 4 pcs

- Reactors volume: 450 ml

- Continuous supply of reagents to all reactors

- Temperature: 20-99 °C

- Continuous pH and ORP control

Technical equipmentFILTRATION

Filter unit, designed for filtration of slurries/solutions under pressure.

Technical specifications:

- Number of cells: 2 pcs

- Filtration area: 0.75 dm2

- Cell volume: 0.09 and 0.15 dm3

- Working pressure: up to 1.0 MPa

- Possibility to wash the cake with hot water

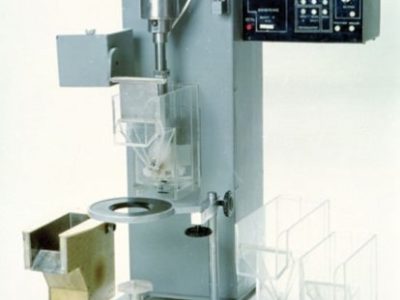

Technical equipmentFLOTATION

Flotation machine FM-3

intended for the investigation of enrichment technological processes for different kinds of mineral raw materials by flotation in laboratory conditions. The flotation machine includes a set of interchangeable cells, cones and impellers.

Technical specifications:

- capacity of exchangeable cells: 0,5; 0,75; 1,0; 1,5; 3,0 dm3;

- the capacity of cell with heating: 0.5 dm3;

- speed control range of the impellers: 500-3500 min-1;

- air consumption in the cell: 0.03-0.25 m3/h;

- the temperature in the heated cell: 25-70 °C.

Technical equipmentPYROMETALLURGY

Laboratory tubular rotary furnace.

The rotation of the tube ensures the continuous movement of the treated material.

Technical specifications:

- Operating temperature up to 900 °C

- The possibility of supplying gases:

- nitrogen

- oxygen

- air